Inspection and Testing

What is Inspection and Testing?

Electrical Inspection and Testing is a procedure completed by qualified electricians. Electrical installations that comply with BS 7671 are likely to satisfy Statutory Regulations such as the Electricity at Work Regulations 1989. Not to comply is a criminal offence and could result in a hefty fine or imprisonment.

Inspection and testing on completion of a new installation

Within BS 7671, Regulation 610.1 states that “every installation shall, during erection and on completion before being put into service be inspected and tested to verify , so far as reasonably practicable, that the requirements of the regulations have been met.” To comply with this regulation, qualified electricians must complete a full inspection and testing procedure. In a case of a new electrical installation, the procedure is followed by the completion of the Electrical Installation Certificate. In a case of an alteration of an existing electrical installation, a Minor Electrical Work Certificate is to be completed.

Periodic inspection and testing

Regulation 621.1 states that “where required, periodic inspection and testing of every electrical installation shall be carried out in accordance with regulations 621.2 to 621.5 in order to determine as far as reasonably practicable, whether the installation is in a satisfactory condition for continued service”. This regulation relates to electrical installations which are not newly built or altered. In this case a periodic inspection is to be carried out. Together with visual inspection it consists of a full inspection and testing procedure and is followed by the completion of the Electrical Installation Condition Report (EICR).

The Inspection and Testing Procedure

To comply with regulations set in BS 7671, qualified electricians must complete a correct and suitable Inspection and Testing procedure. This procedure consists of both visual inspection and tests carried out with the help of suitable testing equipment, such as the Megger 1553 multifunctional tester.

The electrical installation to be inspected can be eider a new build/alteration, in which case an Initial Verification Inspection and Testing procedure must be completed, or an existing electrical installation, in which case a Periodic Inspection and Testing procedure needs to be completed. On the following pages you can learn more about both of these electrical testing procedures.

Electrical Installation

Electrical System Grounding and Bonding

When working on electrical installations, the earth is one of the best safety devices. One may not think of the earth as a device, but when one ground electrical circuits to the earth, it provides protection by diverting dangerous current away into the ground. For this simple reason, in the language of electricians the term “ground” literally means earth. A “ground” is a conductive connection between an electrical circuit or a piece of equipment and the earth or another type of conductive material that is used in place of the earth

Both OSHA and the NEC have very specific requirements for utilizing grounding to reduce the risk of injury. The rationale for these requirements is simple—all electrical installations have to provide a means of transferring electrical current in the event of a circuit fault to reduce potential shock hazards. Grounding protects against shock hazards posed by fault currents. An electrical fault occurs when current flows through an abnormal or unintended path. For example, if the insulation in a conductor is damaged, the means of containing and directing the electrical current running through it will be compromised and ineffective.

A fault current is several times greater than the current that normally flows through a circuit, because it is essentially electricity running wild instead of flowing in a controlled manner. Electricity always follows the path of least resistance, and that path could be you if a fault occurs within electrical equipment or components that have not been grounded.

A Guide to Practical Electrical Installation Work

Basics you should know .

The mode of generating Electricity for various requirements of the mankind today are numerous . Electrical Power Generation methods can be from Thermal, Hydropower, Nuclear ,Solar ,Wind Power or some other form. The generated power is distributed through an Electrical Distribution system.

The Power Utility Companies or Government Power Utility Institutes take the responsibility of bringing the Electrical Power to the Consumer. A Consumer can be a large manufacturing industry or just a Home of a person. The Consumer’s requirements vary greatly according to his electrical power requirements or the useage of Electricity.

Electrical Installations are needed for the Consumer to use Electricity for his requirements as Lighting, Heating and Air Conditioning , running all types of Electrical Equipment , to name a few. It is for the above , that we intend to address here and to gather practical methods and ways for implementation to improve the knowhow on the subject.

First we need to be familier with words such as

Current, Voltage and Resistance and their relationship to each other.

Then about Electrical Power and the relationship to above.

Also about Direct Current,Single Phase ,Three Phase and the Neutral.

Real Power, Apparent Power and Reactive Power

About Earthing and the relationship to the Neutral

The Incoming Supply from the Utility and the Consumer Unit.

About Electric Cables , Main Switches and MCCB units.

Distribution Boards and MCB modules.

RCCB or RCD devices.

Socket outlets and Switches for power distribution and Illumination or Lighting.

Electrical Wiring Diagrams and Electrical Load Calculation to commence an Electrical Installation

Single Phase and Three Phase Supply for Alternative or AC Current usage.

Power Factor and Improving of Power Factor for large Electrical Installations

Work Scope of a general Electrical Installation

* Preparing Electrical Layout Drawings and Schematic Drawings based on Architechtural Drawings

* Determine Electrical Specifications

* List out Material and Component requirements

* Decide Main Distribution Board locations

* Lay conduits or Trunkings in the building as necessary

* Install boxes for Switches and Sockets

* Install Distribution Boards and Main Switches

* Install Cables from Distribution Boards to Switches, Light/Fan points, and Socket outlets [receptacles]

* Install Earth Electrode for the Electrical System.

* Install Lights, Switches, Sockets and other accessories

* Test the Installation and obtain Test Certificate

* Obtain Service Connection from Power Utility Company

* Ready for Commissioning of the Electrical Installation.

Installation Services

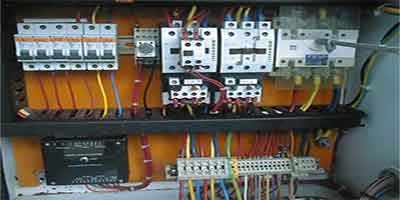

Electrical Panel Upgrades

Electrical panel upgrades are a necessity in preventing electrical issues resulting from the addition of modern, technologically advanced appliances to older homes. In addition, today’s electrical panels offer far more reliability and safety than their outdated predecessors.

Circuit Installations and Upgrades

If your breaker keeps tripping and interrupting your daily workflow, contact for expert troubleshooting and repairs or rewiring.

Ceiling Fan Installation

Don’t let their looks fool you – ceiling fans are heavy, and installations can be long and complicated. Save your back and your patience for other endeavors with prompt, professional installation.

EV Charger Installation and Service

Own a hybrid or electric vehicle? Professionally installed charging stations offer convenience and safety for both your vehicle and your home. Check out our wide range of product solutions including charging stations and circuit protection equipment for all of your hybrid or battery powered electric vehicle needs.

Exhaust Fan Installation

Exhaust fans divert unpleasant odors as well as control temperature and moisture that could lead to damage, mold, and mildew in your home. You can trust for the professional installation and proper sizing that are key to safe, efficient exhaust fan operation.

Home Generators

Having a home standby generator on hand is a good idea for everyone, but especially for people in areas prone to severe weather and power outages.

Commercial Generators

When the power goes out your business needs to keep running smoothly. Put your mind at ease with a backup power generator that will keep your customers and employees comfortable and your computer systems safe and operational.

Commercial Energy Savings and Audits

Operating costs can quickly cut into your business profits. can assess your company’s electrical needs and correct inefficiencies to bring your energy bills down. Often, installing an upgraded ballast and with energy-efficient bulbs, placed strategically, can bring bills down. Get a free electrical wiring inspection to uncover any safety risks or energy waste at your business location.

Commercial Electrical Panel Upgrades

It’s common for the numerous devices and advanced technology needed to run a business today, to simply overwhelm existing electrical wiring. Often, the fix is as simple as an additional electrical panel to ensure you have all the power necessary to run your business, and avoid fire danger, data loss or employee injury.

Electrical Installations

Electrical wiring is done by electricians who install, repair and maintain wiring, switches, conduits, circuit breakers, lighting and other apparatus in buildings and other structures. They need electronics knowledge and trouble-shooting skills to provide maintenance services for electronically controlled systems. Proficiency in all types of electronic applications is important as electricity is used for a variety of purposes, including climate control, security and communications.

An electrician reads and interprets blueprints, plans and sketches, following the variety of methods and practices used in the construction field to complete basic wiring circuits in accordance with the Electrical Code. Electricians need to understand electronics in order to install and maintain the increasing amount of electronic equipment involved in modern construction projects. Keeping up with trends and new technology and continuing to upgrade technical skills is an important part of the job.

Welders perform some or all of the following duties:

Read and interpret drawings, blueprints, schematics and electrical code specifications to determine layout of industrial electrical equipment installations

Install, examine, replace or repair electrical wiring, receptacles, switch boxes, conduits, feeders, fibre-optic and coaxial cable assemblies, lighting fixtures and other electrical components

Test electrical and electronic equipment and components for continuity, current, voltage and resistance

Maintain, repair, install and test switchgear, transformers, switchboard meters, regulators and reactors

Maintain, repair, test and install electrical motors, generators, alternators, industrial storage batteries and hydraulic and pneumatic electrical control systems

Troubleshoot, maintain and repair industrial, electrical and electronic control systems and other related devices

Conduct preventive maintenance programs and keep maintenance records

May install, maintain and calibrate industrial instrumentation and related devices.

Who do they work for?

Residential industry

Commercial industry

Manufacturing

Construction firms

Self-employed

Sample titles

Refrigeration Mechanic

Electrical Engineer

Industrial Electrician

Marine electrician

Mill electrician

Plant electrician

Essential Skills

Reading

Document Use

Thinking (Critical Thinking)

Salary

Between $16.50 and $40.00. Annual salaries between $34,500 to $90,000